A Few Projects

Traceability in petrochemical plumbing

In the petrochemical industry, a leak is synonymous with risks to health, human life and the environment. Manufacturers are therefore subject to stringent standards.

Our brief was to provide a detailed traceability history, including the identity of the welder, when he made the weld, the identity of the inspectors, the dates and times of the inspections, plus all the reports and technical measurements of these inspections.

Armchair storage and distribution

With 400 employees busy making upholstered chairs, we have one entering the warehouse every 30 seconds!

Our mandate was to minimize the time needed to find, assemble and load the armchairs prior to shipment.

Granite traceability: 12,000 KM from cut to office tower

Our brief was to identify an identification technology compatible with the granite constantly watered in production and exposed to the elements, and to develop the software enabling each tile to be traced in real time in the factory, in the outdoor warehouse and, of course, during the several-week journey by boat to produce proof of receipt.

Mobile application: In-store traffic monitoring

The famous problem of counting customers in department stores during the pandemic is an example of a case where part of the technological proof of concept could not be achieved without an MVP.

Our mandate was to create the firmware for the cloud-connected kiosks (IoT), the traffic management software and the mobile application for the store manager.

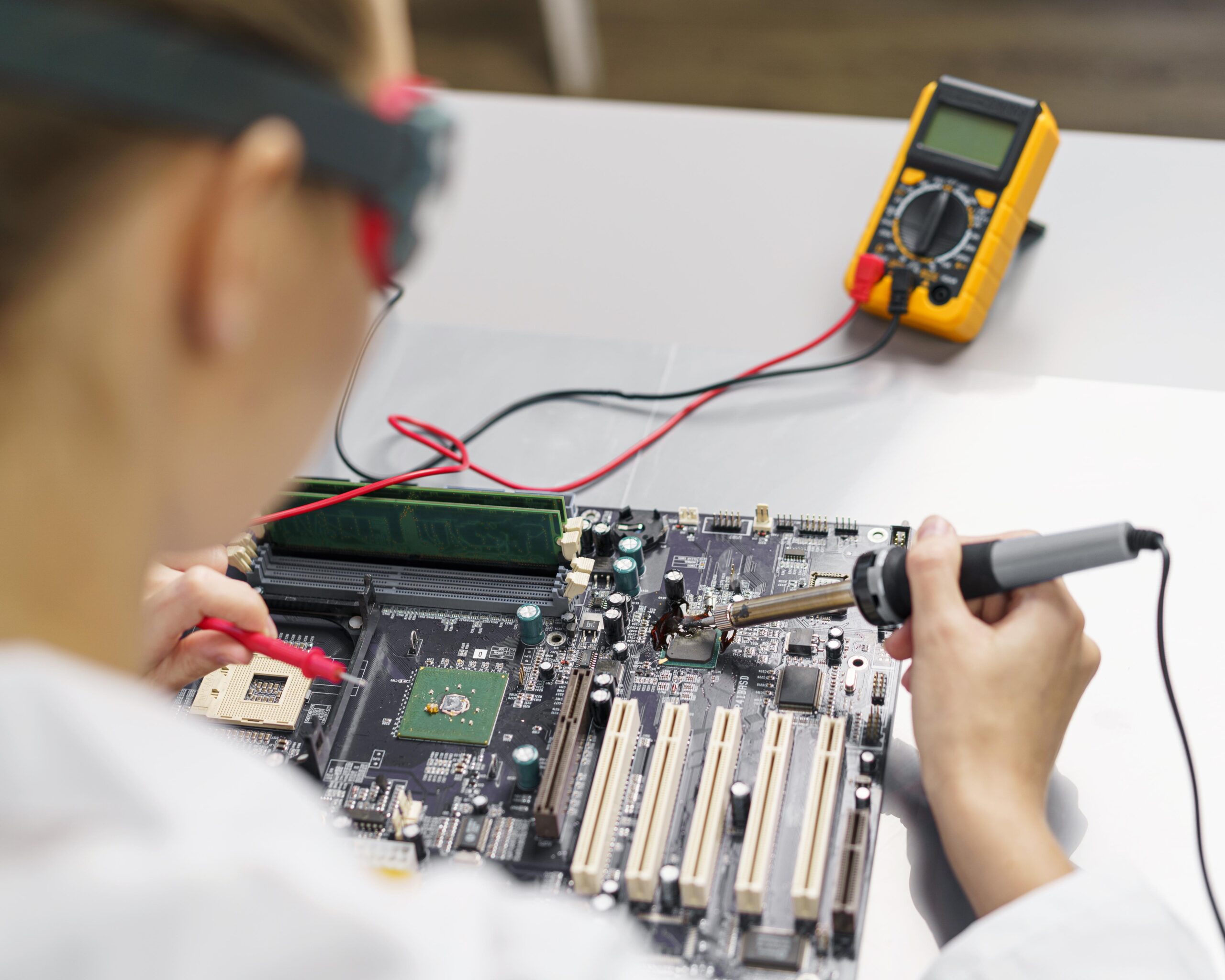

Measurement device certificate management platform

We gave a certification organization the opportunity to eliminate paper management by putting their certificates online, so they can be consulted without delay, without searching, and demonstrate their validity.

Our brief was to create the complete software for the PC and mobile application.

Production management: Pork slaughtering

EIGHT SECONDS is the time between each pork carcass arriving at the cutting room of a modern slaughterhouse. Weight, fat, muscle and other parameters must be measured on each carcass in real time to establish the price paid and ensure the quality of the meat.

Our mandate was to increase infrastructure production capacity by simplifying data collection.